Videx Forging Lines

Automatic or Semi-Auto Magazine Feed

Solid Die Hot Forging 1 or 2 Blows

|

|

|

|

|

|

|

Videx Forging Machines are available in 300, 400 and 500 metric tons of forging power, covering the thread range of M-20 to M-48 (3/4" to 2") in the smallest machine and up to M-80 (3") in the largest machine.

The length range is 200-1,000 mm (8" - 36") under the head.

The hex is formed in a closed die or sliding punch and does not need trimming. The production rate is 4-6 parts per minute!

|

|

|

|

Modular Optional Systems:

- Impact Cutter: Cutting long bars to length.

- Chamfer Machine: Accepting cut-to-length blanks from the Impact Cutter or from a single-row magazine.

- Extrusion Machine: Extruding the chamfered side.

- Induction Heating Station (Induction Unit not made by Videx).

- Forging Machine with Solid Die, Two Blow capability, your choice of 300, 400, or 500 metric tons forging capacity.

Automatic or Semi-Auto versions available.

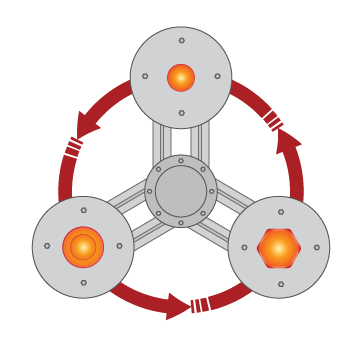

The forging machine has 5 stations; one In-feed station, two forging stations and two ejecting stations.

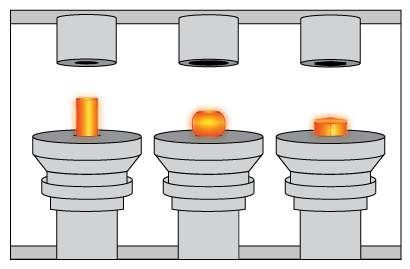

The chamfered and extruded blanks are pushed into the die by a pneumatic piston. Then, the rotary dial indexes the solid die to the first forging station, which upsets the pre-form and breaks the scale.

In the next station, the hex is formed in a sliding punch or closed die.

After heading, the parts are indexed to the ejection station and carried out of the machine via conveyor.

The machine is supplied with a spray system for cooling and lubricating the die and punch.

|